BIG news from Amtech — We're joining forces with Label Traxx 🎉 Read more

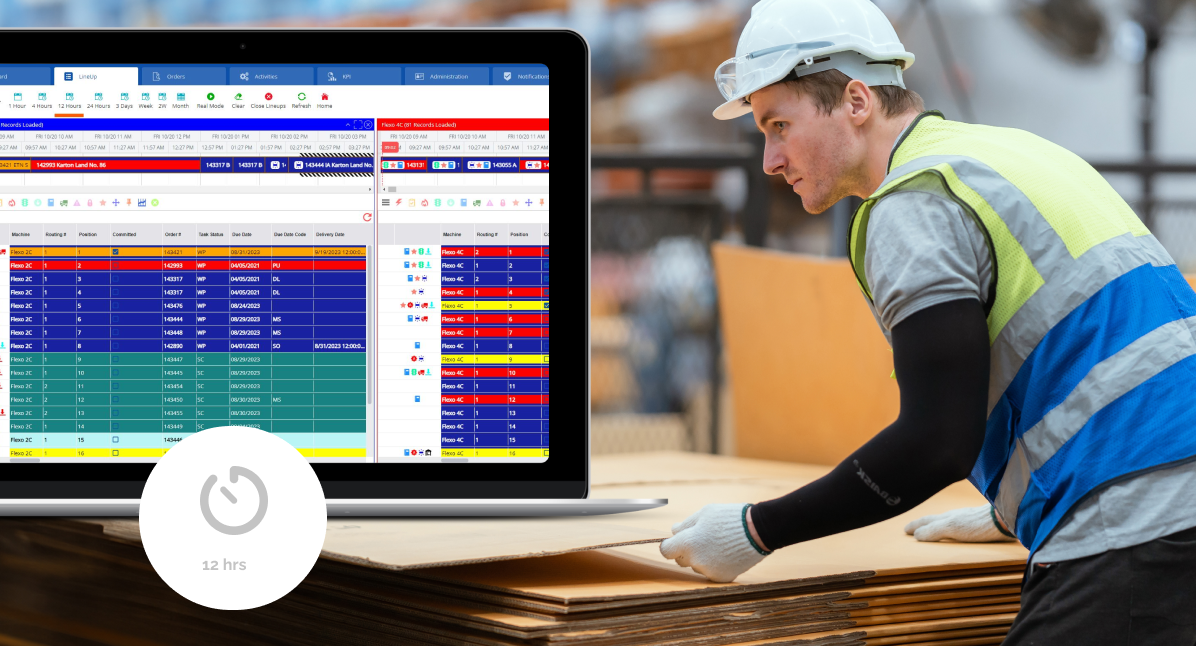

Advanced Planning Board

APB is an automated and integrated plant planning system. Utilizing an automated method to assign point/cost/time-basis for automated scheduling, it sorts order operations at machine centers assuring total balance and optimization of your operational workload. This simplifies the day-to-day tasks of your scheduler and ensures better operational performance to deliver orders, on-time, to your customer.

Increase Throughput.

IMPROVE YOUR SCHEDULING PROCESS

• Delivers automated schedules developed from an intelligent point/cost/time system that considers your entire business.

• Assures proper balance at your machine centers across your organization.

• Optimizes operational workloads toward

orders, inventory, and machinery.

• Simplifies the tasks of your scheduler to be

more efficient and strategic for your business.

• Provides real-time, not near-time, information and visibility across your entire organization through complete integration.

• Improve your bottom-line operational and

business performance.

• Deliver on-time and correct delivery to your

customers.

Electronic flags can be added as "special messaging" to orders for areas such as press-ready, dies approved and materials. This improves cross-departmental communication, electronically, to keep jobs on track and on schedule.

ANALYSIS BY COLOR

• Raw Material and WIP Availability

• Machine and Job Status

• Capacity Availability

• Scheduled Maintenance

• Urgent Orders

• Delivery Status

• Unscheduled Orders

Improve Load Balancing

Flexible Point & Formula System

The Converting Scheduling engine operates off of a sophisticated and flexible point system, based on assigned formulas to support a push and/or pull planning culture depending on business needs through rules established. The system encapsulates operational logistics across your entire operation and appropriately prioritizes orders and reserves machine time. With flexibility, order characteristics are weighted to generate the perfect schedule that optimizes proper load balance and throughput.

Dynamic Scheduling

Using point-based calculations, the system considers historical information for establishing set-up and run speeds delivering an accurate view of the schedule. If an unscheduled downtime event occurs, the system will dynamically reschedule maximizing all available machines. Schedulers can then run quick “what if” scenarios to see the impact on entire operations and schedule. Lineups can be modified from any location-mobilizing the scheduler.

Machine & Load Balancing

Machine balancing is accomplished by using alternate/“like” machines determined by historical run information. This supports immediate decision-making, based on real-time information, for improved capacity management.